Is it possible to “future proof” a superyacht?

The reason for this question is that it doesn’t take much to realise that being able to switch a yacht from fossil fuel to green fuels in the future will have a positive impact on use, cost, and asset value.

Whilst these concerns, and the transition away from fossil fuels, seems to be far away, the impetus is growing and the reality is that when you take into account the design and build cycle, along with the lifetime of a superyacht, you begin to understand why this may be an important consideration for anyone investing in a new-build today.

Indeed, Lurssens announcement of a project using Methanol and Fuel Cells may represent a paradigm shift for the industry. Though there are still questions about the availability of Green Methanol, this is probably only one of two superyachts in build that have the potential to adapt to a low carbon future.

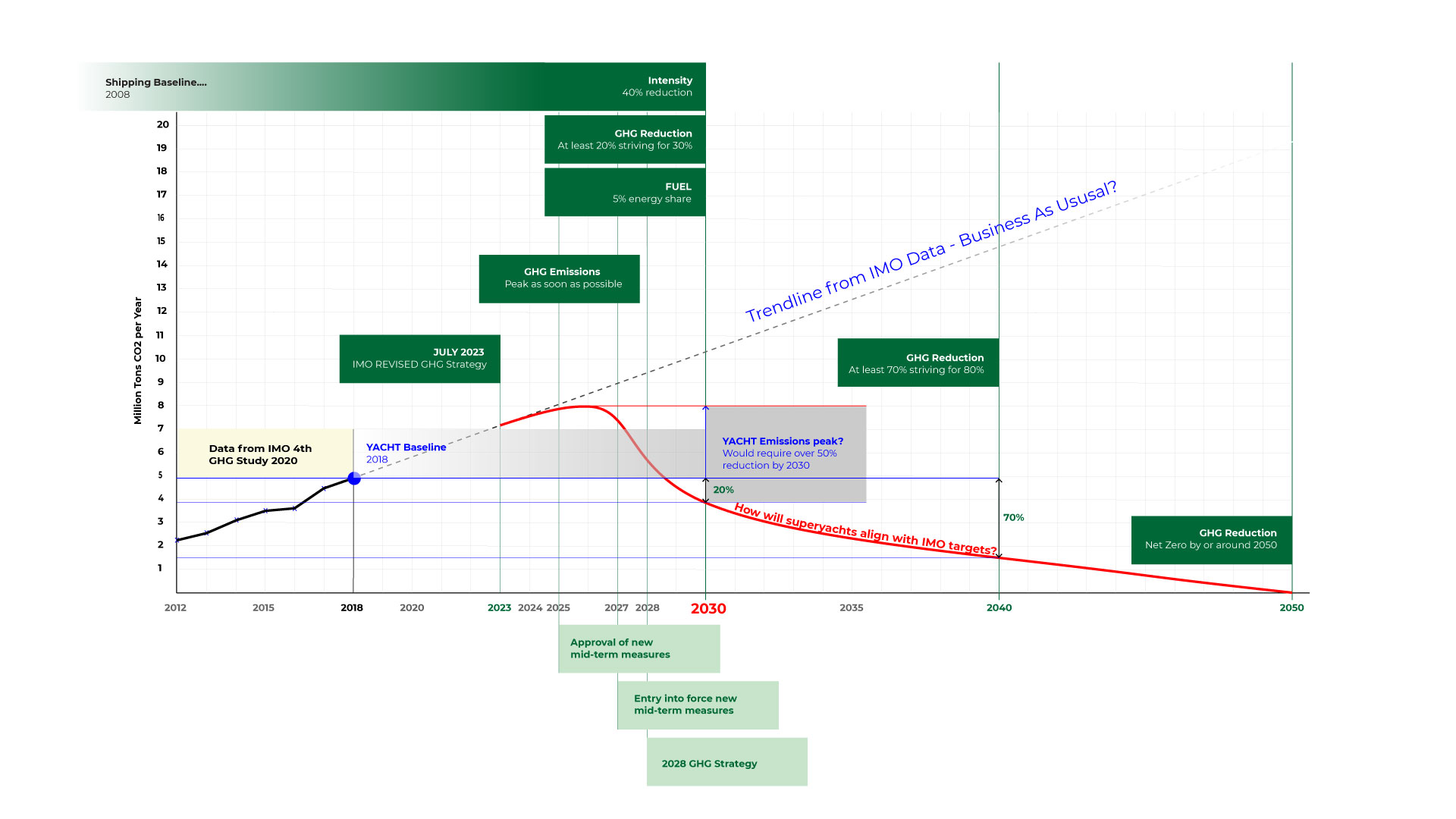

It is clear that Global Warming and the environment is becoming an important consideration for some owners, and the pressure for our industry to act will only intensify in the coming years, whether through regulation, taxes, public sentiment or, more likely, a combination.

The current narrative from many in the industry seems to be that ‘”electrification” will allow an owner to simply remove the generators and replace them with Fuel Cells. On the surface this seems to make sense, however they always conveniently ignore the energy carrier (fuel) so the reality is a little different.

It’s All About The Fuel

When you look more deeply at this, the challenge will not come from the replacement of the generators, it will come from the choice of the energy carrier that replaces the fossil fuel and how you store it onboard.

Currently Hydrogen, Methanol and Ammonia seem to be the leading contenders in the drive to decarbonise shipping. Though, as recent reports have suggested Hydrogen, is not considered practical for for Ocean going ships, and Ammonia has significant hurdles to overcome. LNG and biofuels also provide a useful pathway that will help reduce emissions but are unlikely to be the long-term solution – issues include feedstock availability and fugitive Methane emissions – Methane is 84 times the equivalent CO2 Global Warming Potential (GWP) over a 20 year life time.

The production of ‘E’ Ammonia or Methanol, requires Green Hydrogen produced via electrolysis using renewable electricity, and synthesis with air (E-Ammonia) or CO2 (E-Methanol). It is an energy intensive process. Methanol also requires a supply of CO2 either via industrial Carbon Capture and Utilisation (CCU) or Direct Air Capture (DAC) and, in the case of Bio-Methanol, a plentiful supply of feedstock.

You can read more about Methanol here>

Due to the amount of energy required to produce these fuels and the supply chain costs, alternative fuels are forecast to be more expensive than today’s fossil fuels. Whilst scale may help to bring down prices and carbon taxes may help with the competitiveness, energy efficiency through technology and innovation will still be necessary to reduce energy consumption and cost.

Worth noting is that Hydrogen, Ammonia, and Methanol, can be used in internal combustion engines (ICE) as well as Fuel Cells.

Methanol is gaining traction in the commercial shipping sector. The Ro-Ro/Pax carrier, Stena Germanica was successfully converted to run on Methanol and Maersk has ordered a number of large container ships to run on Methanol in dual-fuel engines.

Rolls Royce MTU recent announcement of Methanol 4000 series engines also highlights the potential for the superyacht industry – more engine types and manufacturers will no doubt follow.

Volumetric Density

The major challenge with all these fuels for yachts, where space, the high cost of the real-estate, and aesthetics, are major factors – a cryogenic tank on the aft deck, or less guest space would not be ideal – is that they are less energy dense than diesel. They require more volume for the same amount of energy, and special storage and enhanced safety features due to the nature of the fuels.

This excellent diagram of Volumetric and Gravimetric energy of various fuels from DNV-GL – Comparison of Alternative Marine Fuels, Report No: 2019-0567, Rev. 3, clearly highlights the energy differences.

Apart from Methanol, there is also a lack of a regulatory framework for their use as a marine fuel. More information on Methanol as a fuel an be found in The International Maritime Dangerous Goods (IMDG) Code, International Code of Safety for Ship Using Gases or Other Low-flashpoint Fuels (IGF Code) and IMO MSC.1/Circ.1621 Interim Guidelines For The Safety Of Ships Using Methyl/Ethyl Alcohol As Fuel.

Hydrogen, due to its volumetric density and storage requirements in compressed or liquid form, probably excludes its use directly as a marine fuel on superyachts, though, as with commercial shipping, it may be well suited to coastal operation, short-shipping. More likely, as with the Lurssen project, is that Methanol is used as the energy carrier, either directly in ICE, converted into Hydrogen using reformers onboard for Fuel Cells, or a hybrid solution combining both energy convertors.

There are now a number of shipyards that are developing platforms designed to be “fuel-flexible” including ensuring they are Methanol-ready so that they can use the fuel now, or in the future.

Of note is that all alternatives to diesel (fossil or bio) will also require investment in the human capital as their use will demand higher levels of training and safety.

Future Proof Questions

So when you see a shipyard or other stakeholder advertise their yacht as “future proof”, ask them the following questions:

- Is the electrical network ready for alternative energy convertors

- What fuel will the Fuel Cells use

- Is the yacht built “fuel flexible” e.g. Methanol ready

- Is it Class and Flag approved

- Will the fuel storage need to be converted

- What are the impacts on cost, space and range