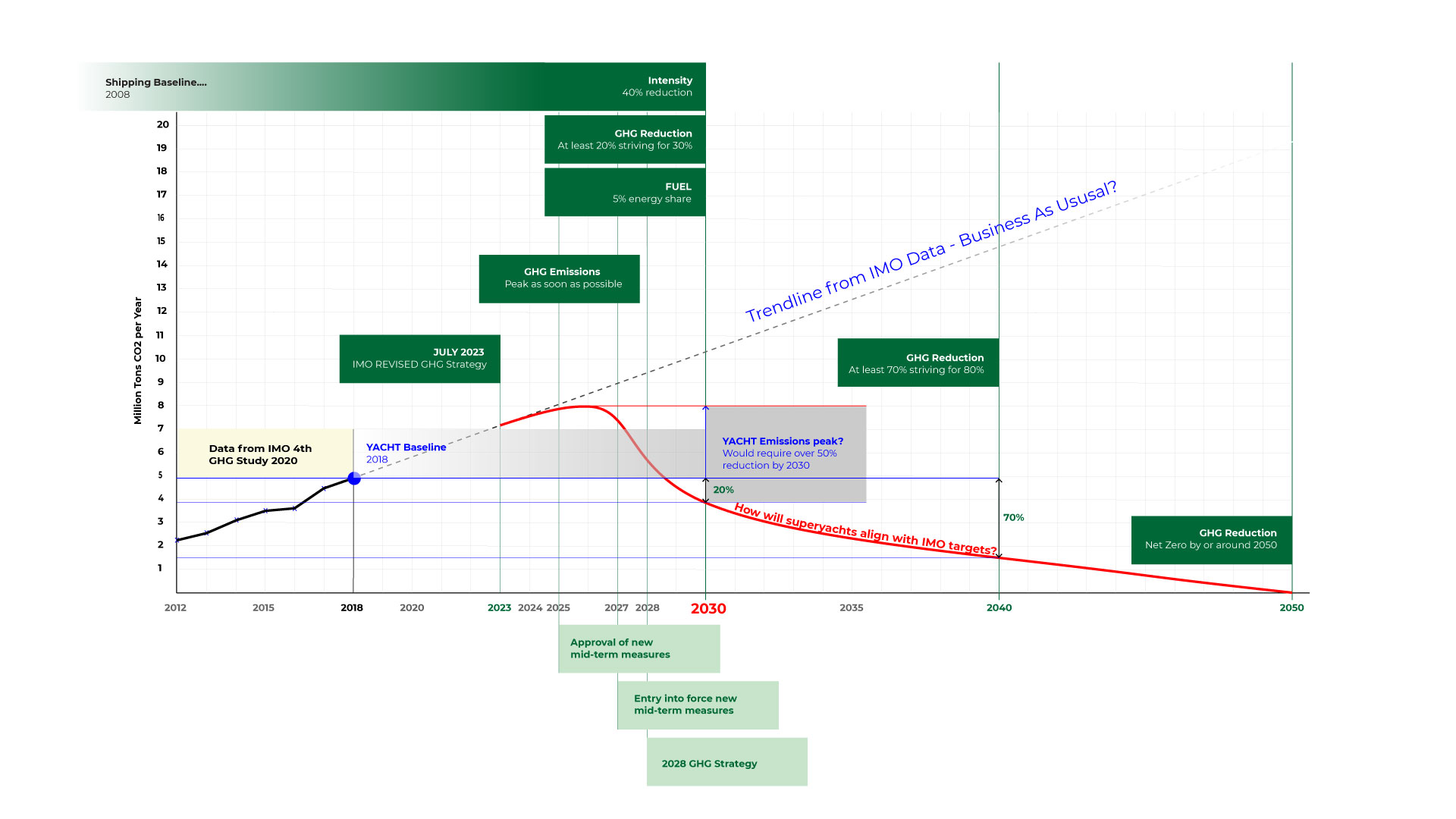

There has been a lot of focus on new technologies and green fuels such as hydrogen and methanol as a means of decarbonising the superyacht industry. While these will offer solutions for new-builds in the future, what about the large fleet of recent builds and legacy vessels, how can they reduce their carbon emissions?

These yachts may be difficult to fully decarbonise but there are operational changes that can be made to reduce emissions. There are also companies who are developing upgrade packages that will help improve energy efficiency – something that could be a big market for the refit sector in years to come?

In addition, there are renewable liquid fuels or Renewable Diesel (RD) such as FAME (Fatty Acid Mythel Ester) and HVO (Hydrotreated Vegetable Oils). Although they can be produced from the same feedstock such as vegetable oils e.g. soybean, peanut oil and palm oil, animal fats, and waste oils, the process and end product is different.

Depending on the feedstock and production process, on a Well-to-Wake (WtW) measure, FAME and HVO can reduce CO2 emissions by up to 90%.

A Little History

Use of vegetable oils in engines is not new.

Historical records suggest Rudolf Diesel was the first to use ‘peanut oil’ to run one of his engines in 1893. And in 1900 at the Paris Exhibition, the French Otto company demonstrated one of their unmodified fossil diesel engines running also on peanut oil.

Interestingly, in 1912, a year before his death, Rudolf Diesel gave a speech in which he mentioned:

“the use of vegetable oils for engine fuels may seem insignificant today, but such oils may become, in the course of time, as important as fossil and the coal-tar products of the present time.”

Since then, various influences such as cheap fossil fuels, war, socio-economics, concerns over energy dependency, government policies and more recently climate change have shaped the evolution and uptake of biofuels.

Fuel Feedstocks

Although first generation of biofuels reduced CO2 emissions, concerns remain over land use and the issue of fuel vs. food.

This is where land is altered or repurposed from growing food to producing crops for fuel. This demand for land has caused widespread deforestation in countries like Indonesia and Malaysia for the growing of palm oil crops. And there is some suggestion that the deforestation and soil degradation from single crops, reduces or cancels the CO2 benefits of biodiesel. Therefore, feedstock and production process are critical.

In the EU, under RED II (Renewable Energy Directive) they consider Biofuels, and Advanced Biofuels.

Biofuels are produced from lignocellulosic feedstocks (i.e. agricultural and forestry residues, e.g. wheat straw/corn stover/bagasse, wood based biomass), non-food crops (i.e. grasses, miscanthus, algae), or industrial waste and residue streams, waste oil and animal fats, and has low CO2 emission or high GHG reduction, and reaches zero or low ILUC (Indirect Land Use Change). These feedstocks can all be found in Annex. III.

Engine Compatibility

Most engine manufacturers will have specific fuel recommendations for their engines, including the use of biofuels and alternative fuels.

As an example, Caterpillar publish a document called ‘Caterpillar Machine Fluids Recommendations’ in which there are specific recommendations on the use of Biodiesel in non-road transport engines.

In the 2019 version of their publication, they also state that if a renewable or alternative fuel fulfils the performance requirement in the CAT Fuel Specification, the latest versions of ASTM 975, EN 950, or EN15940, it can be used as a direct replacement of fossil diesel in all CAT diesel engines.

Note: as a precaution, before using any biofuels or alternative fuels it is recommended to contact your engine manufacturer for clarification.

Biodiesel FAME

The oils are extracted from plants normally by pressing – waste oils must undergo additional process required to remove the Free Fatty Acids (FFA). The oil then goes through a process called ‘transesterification’. This is where, under temperature, methanol and a catalyst are added to produce Fatty Acid Methyl Ester (FAME).

FAME is often blended at low levels with fossil diesel to ensure compatibility, performance, and stability. Low level blends ensure that they can be used in engines without modifications.

In the USA up to 5% FAME can be added to fossil diesel under fuel standard ASTM D975 without the need to declare its presence.

EN 950 is a fuel standard that allows a maximum 7.0 vol-% of FAME as a blending component with fossil diesel.

Renewable Diesel HVO

HVO stands for Hydrotreated Vegetable Oil, this comes from a time pre-2010 when vegetable oils were the only feedstock. Depending on feedstock and production method its considered an Advanced Biodiesel under RED II.

The feedstock is first undergoes ‘hydro-treatment’ at high temperature and pressure, where hydrogen added to remove the oxygen, followed by ‘hydro-processing’ which determines the product e.g., sustainable aviation fuel (SAF) or renewable diesel.

HVO is a non-oxygenated, paraffinic diesel fuel that conforms to the standard EN 15940. It is chemically similar to fossil diesel and is considered to be ‘drop-in’ a diesel fuel replacement.

What’s in a Label

EN 950 is a fuel standard that allows other blending products to be used, and it makes no distinction on feedstock or production.

EN 15940 is a fuel standard that covers all paraffinic synthetic diesel fuel. In the EU it is also labelled as XTL. It does not differentiate the feedstock or production process, and can include Coal to Liquid (CTL) Gas to Liquid (GTL) Biomass to Liquid (BTL) products, as well as HVO.

At retail fuel stations in Europe, at the pumps you will see B7, B10, B20, B30 and B100 depending on the biodiesel content, and XTL for all synthetic diesel.

This lack of clarity over feedstock, production, and fuel standards, means care is required to ensure they have the best GHG outcomes and least food/land impact.

HVO Benefits

- It is a direct replacement for fossil diesel,

- With the right feedstock and production process, used at 100% it can reduce CO2 emissions by up to 90% WtW

- Very low sulphur content

- NOx is reduced, though exhaust gas after treatment may still be required to reach Tier III specifications

- Low smoke, soot, and particulates

- Clear (above cloud point) low odour and biodegradable

- Microbial growth similar to fossil diesel

- Storage stability similar to fossil diesel

- Can be mixed with fossil diesel

Energy Content and Density

By Weight

MJ/kg

By Volume

MJ/l

Specific

Density

Diesel

43

36

~835

HVO

44

34

~780

FAME

37

33

~880

As can be seen in the table HVO has a slightly higher energy density than fossil diesel by weight but, it has a lower energy density by volume.

Performance

Without changes to timing, fuel rack, injectors, to optimise engines for HVO, the lower volumetric energy density of HVO means that for the same engine power output, although the engines would run cleaner, there may be a slight increase in fuel consumption.

Lubrication

To avoid excessive wear, fuel must have a minimum level of lubricity. The use of fuels with poor lubricity can increase fuel pump and injector wear and, at the extreme, cause a total failure. Hydrotreated fuels like HVO typically have poor natural lubricity – this is easily resolved by treating the fuel with a lubricity additive. This can be added prior to supply.

Challenges

There are two major challenges with HVO: –

- Production/availability

- Cost

Whilst the production process is mature and there are number of companies now producing HVO, compared to fossil diesel, it is currently in low volumes. This means it may not always be easily available, especially in more remote locations. However, in Europe and, possibly the USA, with a little forward planning it can be a practical alternative.

HVO and fossil can be mixed and used interchangeably so, for example, you could use HVO in the Mediterranean and switch to fossil diesel in the Caribbean, without any problem.

Due to the high cost of the feedstocks and production process, and renewable energy, HVO is around 2 – 3 times more expensive than fossil diesel – this creates resistance to more widespread use. Though, if you can afford a superyacht, you can afford the price of a less damaging fuel?

Cost is also one of the reasons why energy efficiency will be key in the future.

This was highlighted in a recent discussion with a yacht owner, who was very serious about wanting to mitigate his yachts CO2 emissions. However, once he digested the cost impact of HVO, he very quickly chose cheap ‘carbon offsets’ as an alternative. This was despite the fact he agreed HVO had an immediate impact, and many carbon offset schemes were of questionable value.

However, once he digested the cost impact of HVO, he very quickly chose cheap ‘carbon offsets’ as an alternative.

In the future the price differential will close, not because of increased production capacity, as feedstock will remain high and competition from other industries, such as aviation, but due to incentives like reduced duty on low carbon fuels or carbon taxes on fossil fuels.

For example, in Finland from August 2020 they are applying an energy tax, CO2 tax and a security of supply levy, that reduces the duty on fuels like HVO by approx. €0.31/l compared to fossil diesel.

In the EU, as part of their ‘Fit For 55’ package, the Emissions Trading System (ETS) is going to be applied initially to ships 5000GT and over. Phased in at 20% in 2023 and rising to 100% by 2026. The price of ETS Carbon Credit (CC) is getting very close to €100 t/CO2 – at 100% would add €380 to a ton of fossil diesel based on EU WtW factor of approx. 3.8 t/CO2 per ton of MGO/MDO.

Conclusion

There is no doubt that HVO is a great alternative for superyacht owners who want to make a real and measurable difference to their yachts CO2 emissions.

For example, a two season 65m motor yacht, based on an annual consumption of 1000t MGO/MDO, could save the CO2 emissions equivalent to 2585 cars (av. 130 gCo2/km, 11300 km per annum).

Though price and availability will remain as challenges in the short term, HVO offers a very real solution, even for older yachts, to significantly reduce their CO2 emissions and demonstrate a more responsible approach to yachting.